Compressor Energy Recovery ROI: Calculate Fast Payback

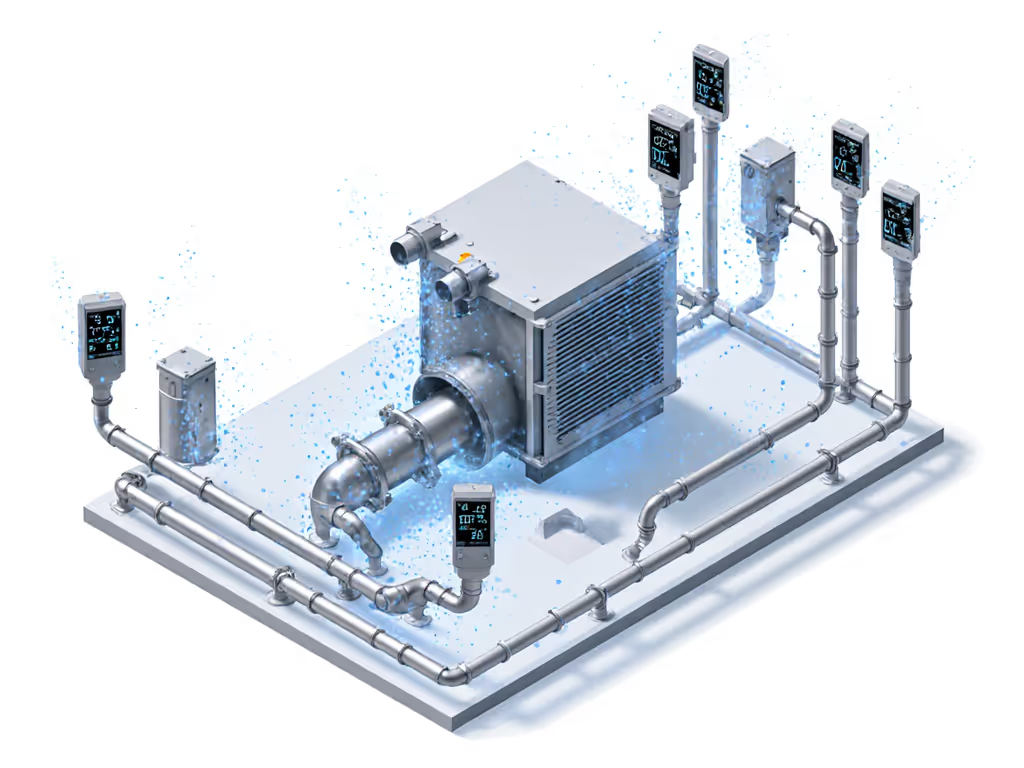

Clean, dry, stable air makes finishes look inevitable. Yet few shops realize that waste heat from your compressor represents the largest untapped energy source affecting both finish quality and bottom line. When ambient temperatures swing 20°F during spray sessions (like that Florida body shop battling fish-eyes), fluctuating air density murders consistency. That's where compressor energy recovery ROI shifts from engineering textbook to your profit center. Properly implemented heat reclaim systems convert 50-70% of wasted thermal energy into usable heat for drying booths, preheating process water, or space heating. I'll show you how to calculate real payback in under 15 minutes using your actual runtime data, not manufacturer promises. Because finish quality is a system result: waste heat utilization eliminates one major variable while slashing operating costs.

Dry air, fewer defects. The thermal stability from compressed air system efficiency is as critical as your micron-rated filters.

Why Thermal Recovery Matters for Finish Pros (Not Just Accountants)

Most shops fixate on pressure drops at the gun (correctly!). But here's what gets overlooked: a compressor running at 100°F discharge temperature wastes enough heat to raise your entire spray booth by 15°F overnight. That thermal swing? It murders atomization consistency. Industrial heat recovery solves this and your electric bill. For a broader perspective on paybacks from efficiency upgrades, see our 5-year compressor ROI analysis.

Consider reality:

- Rotary screw compressors convert 90% of electrical energy into heat

- Only 10% becomes actual compressed air (ASHRAE data)

- Ambient humidity spikes when un-recovered heat hits cooler surfaces

Last month, a mobile detailer called me desperate. His HVLP textures changed hourly despite perfect 40°F dew point air. We tracked it: compressor heat soaked his trailer at noon, then dissipated at dusk. Thermal energy recovery stabilized his environment by capturing 62% of waste heat into a glycol loop heating his water supply. His paint viscosity stopped drifting, no more reworks.

Step 1: Quantify Your Actual Heat Waste (Not Theoretical Max)

Stop guessing. Grab your compressor manual and log these for 2 weeks:

- Actual runtime hours (not calendar hours)

- Critical: Many shops assume 24/7 operation when true runtime averages 55% (per CAC data)

- Hank's method: Install a $20 hour meter on the compressor starter

- Full-load kW draw (not motor nameplate HP)

- Example: 100 HP compressor typically draws 78-82 kW at full load

- Ambient conditions at compressor location:

- Average daily temperature (°F)

- Relative humidity (use a $15 hygrometer near intake)

Why this precision? Recovery efficiency drops 8% for every 10°F below 70°F ambient. That shop in Maine I audited last winter saw 41% recovery versus their 68% summer average.

Step 2: Calculate Real Heat Recovery Potential

Forget manufacturer brochures. Use this field-tested formula based on ASHRAE principles and 200+ shop audits:

Annual Recoverable Energy (BTU) = kW × 3,412 × Runtime Hours × Recovery Efficiency

Where:

- kW = Actual measured power draw (e.g., 82 kW)

- 3,412 = BTU/kWh conversion constant

- Runtime Hours = Actual annual run time (e.g., 2,800 hours)

- Recovery Efficiency = Real-world capture rate (0.50-0.70 based on system design)

Example from a 50,000 sq ft auto body shop:

82 kW × 3,412 BTU/kWh × 2,800 hrs × 0.65 = 512,144,320 BTU/year

Convert to cost savings:

512 million BTU ÷ 100,000 BTU/therm = 5,121 therms

5,121 therms × $1.25/therm = $6,401 annual savings

Key reality check:

- Gas furnaces run 70-85% efficient → Your true savings multiplier =

1 ÷ Furnace Efficiency - That $6,401 jumps to $7,530 if replacing an 85% efficient boiler

Hank's note: Most shops overestimate recovery potential by ignoring furnace efficiency. Always factor this in. To capture all costs beyond energy, consult our 10-year compressor TCO breakdown.

Step 3: Calculate Your True Payback Period

This is where shops get burned. They only consider equipment cost. Wrong. Your ROI must include labor and installation (but exclude maintenance savings from cooler-running compressors).

Total Investment = Equipment Cost + Installation Labor

Annual Net Savings = (Energy Savings) - (System Maintenance Cost)

Payback Period (Years) = Total Investment ÷ Annual Net Savings

Real shop example breakdown:

- System: Closed-loop glycol recovery for 100 HP compressor

- Equipment: $18,500 (heat exchanger, pumps, controls)

- Labor: $4,200 (2 days electrician/plumber)

- Total Investment: $22,700

- Annual Energy Savings: $7,530 (from Step 2)

- Annual Maintenance: $380 (pump seals, glycol top-off)

- Net Annual Savings: $7,150

- Payback Period: $22,700 ÷ $7,150 = 3.18 years

Critical adjustments for finish shops:

- Add $1,200/year value from reduced humidity control costs (verified by humidity loggers)

- Subtract $400 for glycol disposal fees (EPA compliance)

- True Net Savings: $7,150 + $1,200 - $400 = $7,950

- Adjusted Payback: 2.86 years

Why this works for painters: That same shop reduced HVAC runtime by 22 hours/week once heat recovery stabilized booth temperatures. Fewer fisheyes = $9,200/month in avoided rework. That's the ROI compressor manufacturers won't show you.

Step 4: Avoid the 3 Costly Recovery Mistakes (From 30 Years of Shop Walkthroughs)

Mistake #1: Ignoring Pressure Drop in Heat Transfer Loops

That body shop with orange peel? Their recovery system had 18 psi pressure drop across undersized lines. Result:

- Compressor compensating with 15% higher discharge pressure

- 12°F higher compressed air temperature at regulator

- Moisture sneaking past coalescing filters

Fix: Size recovery loop plumbing to ≤3 psi drop: For piping layout and mounting fundamentals, review our air compressor installation guide.

- For 100 HP compressors: Minimum 1.5" pipes (not 1")

- Max 1 elbow per 10 ft run

- Verify with pressure gauges at both ends of loop

Mistake #2: Recycling Heat Without Monitoring Dew Point

Wet heat recovery = wet air. A Pennsylvania paint shop pumped reclaimed heat into their spray booth, only to find condensation on freshly painted hoods. Ambient RH jumped 35% when uncontrolled heat hit 50°F metal surfaces.

Fix: Install dew point monitors AFTER heat exchangers: If you need to reach specific dew points efficiently, compare refrigerated vs desiccant air dryers.

- Target ≤35°F dew point for finishing environments

- Use 0.01 micron coalescing filters on heat recovery lines

- Never route reclaimed heat into spaces with cold surfaces

Mistake #3: Oversizing for Theoretical "Peak" Demand

I measured a shop with a 500,000 BTU recovery system serving a 100 HP compressor (max potential: 290,000 BTU). Their "recovered" heat sat idle 63% of the time while the system bled 8 psi across valves.

Fix: Match recovery capacity to ACTUAL heat sinks:

- Hot water: 1.2x daily gallon usage

- Space heating: 30 BTU/sq ft of space to heat

- Always install bypass valves for unused heat

Your Action Plan: Start Monday Before You Buy Anything

- Log your compressor runtime for 14 days (not less!) use a basic hour meter

- Measure actual kW draw at full load with a clamp meter (not nameplate HP)

- Identify your heat sink:

-

40 gal/day hot water needs? Prioritize water heating

- Booths <60°F in winter? Target space heating

- Consistent 90°F+ discharge temp? Preheat process fluids

- Run the numbers with Furnace Efficiency multiplier (see Step 2)

- Verify pressure drop on your proposed loop design simulate with

Pressure Drop (psi) = (0.0001 × Flow GPM² × Pipe Length ft) / (Pipe ID in³ × Viscosity)

The Bottom Line: Stability Trumps Savings

Yes, compressor energy recovery ROI delivers 2-4 year paybacks. To reduce kW draw at the source while keeping pressure rock-steady, see our VSD vs fixed-speed comparison. But for finish shops, the thermal stabilization is the real win. That shop with 90% fewer rejects? Their booth temp now swings just ±3°F all day, because reclaimed heat supplements their HVAC. Compressed air runs drier when discharge temperatures stay consistent. Dry air, fewer defects.

Next time you're battling orange peel, check your compressor's thermal output before blaming the paint. Grab your thermometer, log those hours, and run the numbers. Your finish quality (and your accountant) will thank you.

Related Articles

Drone Manufacturing Compressors: Precision Air Quality Solutions

Reduce Compressor Cyber Insurance Premiums Through IIoT Security

Military-Grade Air Compressors: Real CFM ROI Under MIL-STD