VSD vs Fixed Speed: Energy Savings Through Stable Pressure

When compressed air wavers at the tool, finishes fail, regardless of paint quality. That's why VSD vs fixed speed compressor decisions hinge on one truth: pressure stability dictates output quality. A variable speed drive comparison isn't just about energy bills; it's about whether your HVLP gun gets 90 psi consistently during a clear coat pass. I've seen too many shops blame paint chemistry for fisheyes when their compressor dropped to 35 psi at the trigger. Clean, dry, stable air makes finishes look inevitable.

As a spray finishing specialist, I've mapped air systems where 28 psi at the tool (vs. 100 psi at the tank) caused orange peel on a $5,000 respray. The fix? Not new paint, but a VSD compressor, shorter hoses, and regulator placement that stabilized pressure. Today, I'll walk you through a step-by-step process to quantify where VSD earns its keep, and where fixed speed still wins. Follow this strictly to Finish to spec, repeatably.

Step 1: Map Your Air Demand Profile (The Critical First Step)

Guessing demand patterns wastes money. Before choosing compressors, document actual usage:

Document Real-World Usage Patterns

- Measure peak/low demand: Use a flow meter (e.g., Brooks Instrument 0154) at the main line. Log data for 72 hours across shifts.

- Track pressure at the tool: Not the tank. Attach a digital gauge (like Vaultz VZ-500) to your spray gun inlet. Note fluctuations during trigger pulls.

- Record ambient conditions: Dew point and RH impact drying needs. If RH >60% or dew point >50°F, oversize drying by 25%.

Demand Profile Examples

| Scenario | Typical Demand Curve | VSD Advantage | Fixed Speed Fit |

|---|---|---|---|

| Auto body shop | Spikes during sanding/spraying (70-100 CFM), idle 5+ mins | ✅ 38% energy savings | ❌ Frequent cycling |

| Woodshop (constant nailing) | Steady 25 CFM, 24/7 | ❌ 15% energy penalty | ✅ Minimal cycling |

| Mobile detail rig | Bursts (90 CFM for 90 sec), 20-min idle | ✅ 47% energy cut | ❌ Pressure drops |

Key Insight: VSD shines when demand fluctuates >30% of max capacity. Fixed speed wins for steady loads >70% of max CFM.

Your Action Checklist

- Run flow/pressure logs for 3 shifts minimum

- Identify % time spent below 50% max demand

- Calculate demand fluctuation handling index:

(Peak CFM - Min CFM) / Avg CFM

- >0.6 = Strong VSD case

- <0.3 = Fixed speed viable

Step 2: Calculate Energy Savings & Payback (The Math You Can't Skip)

Marketing claims lie. Verify savings with shop-specific energy savings calculation: For a full financial model with incentives and payback scenarios, see our compressor ROI analysis.

The Real-World Formula

Annual Savings = (kW_fixed - kW_vsd) × Hours × Electricity Rate

Where:

kW_fixed= 0.25 HP/CFM × Max Demand (for fixed speed running at 100%)kW_vsd= 0.25 HP/CFM × (Avg Demand × 0.65) [VSD's part-load efficiency advantage]

Example: 100 CFM shop, 2,000 hrs/yr, $0.12/kWh

- Fixed Speed: 25 kW × 2,000 × $0.12 = $6,000/yr

- VSD: 16.25 kW × 2,000 × $0.12 = $3,900/yr

- Savings: $2,100/yr

Compute Your VSD payback period

Payback (years) = (VSD Cost - Fixed Cost) / Annual Savings

Using 100 CFM units ($18k vs $14k):

- Payback = ($18,000 - $14,000) / $2,100 = 1.9 years

Variables That Change the Math

- Utility rebates: Many utilities offer $1,500-$5,000 for VSDs (e.g., PG&E's TECH program)

- Inverter compatibility: VSDs often work with generators (critical for mobile rigs)

- Noise costs: VSDs run 5-8 dBA quieter, reducing hearing fatigue during 8-hr shifts

Pro Tip: A 100 CFM VSD paid for itself in 14 months at a mobile collision trailer. Their generator fuel savings alone covered 30% of the cost.

Step 3: Pressure Stability Testing (Where Finish Quality Lives or Dies)

This is non-negotiable. VSD's real value isn't just energy, it's stable pressure at the tool. Here's how to verify it:

How to Test for Pressure Drop

- Baseline measurement:

- Install gauge at tank outlet (100 psi)

- Attach identical gauge to spray gun inlet (record idle/run pressures)

- Run application test:

- Spray 200 sq ft panel with HVLP

- Note pressure dip during 30-sec trigger pulls

- Compare compressor types:

| Compressor | Tank Pressure (psi) | Gun Pressure (psi) | Pressure Swing (psi) | Finish Impact |

|---|---|---|---|---|

| Fixed Speed | 98 → 82 | 90 → 68 | 22 | Orange peel, fisheyes |

| VSD | 97 → 94 | 89 → 85 | 4 | Glass-smooth |

Critical Fixes for Fixed Speed Setups

If VSD isn't feasible, implement these immediately:

- Add regulator at tool: A 1/4" Norgren R07-100-G replaces 50 ft of 3/8" hose

- Shorten hose runs: 25 ft max with 3/8" ID (50 ft drops 17 psi at 25 CFM)

- Install desiccant dryer: -40°F dew point stops moisture even during pressure swings

ECHOGEAR Sound Bar Mounting Bracket for Under TV

Step 4: Build Your System for Repeatability (Not Just Efficiency)

VSD alone won't save finishes. Integrate it into a full air treatment chain:

Hank's Spec-Grade Air Chain

Compressor → Aftercooler (10°F approach) → 5-micron filter → Refrigerated dryer → 0.01-micron coalescing filter → Desiccant tower (-40°F) → Regulator at tool

Critical Placement Rules

- VSD Advantage: Maintains pressure during demand spikes, preventing dryer overload

- Hose diameter: Never undersize below 3/8" for HVLP guns (25+ CFM tools)

- Pressure drop chart: 50 ft of 5/16" hose at 40 CFM = 22 psi loss

- Regulator at tool: Essential for VSD systems, dampens residual fluctuations

When Fixed Speed Still Wins

Use fixed speed only if:

- Demand is steady >70% of max CFM (e.g., constant sanding line)

- Upfront cost < $10k AND <500 hrs/yr runtime

- Ambient RH <40% AND no precision finishing

Hard Truth: If you're seeing fisheyes or texture issues, pressure instability, not paint, is the culprit 9 times out of 10. Verify at the tool.

The Bottom Line: Match the Machine to the Mission

VSD vs fixed speed compressor choices determine more than energy bills, they define whether your finishes meet spec. For shops with demand fluctuation handling >30%, VSD pays back in <2 years while eliminating pressure-related rework. Fixed speed remains valid for high-duty, steady loads, but only with regulators at the tool and shortened hoses.

Last month, a Tennessee frame shop slashed rejects by 85% after switching to VSD. Their mistake? Blaming the paint when pressure at the gun dipped to 41 psi during sealer application. We dialed in a VSD compressor with desiccant drying and 20-ft hose runs. Finish to spec, repeatably.

Your Next Step

Run the demand profile test in Step 1. With actual data, VSD's value jumps from "maybe" to "mandatory." Check your local utility's rebate page first, many programs require proof of current pressure instability. Need help interpreting your logs? DM me your pressure curve and I'll flag critical drop zones.

Author's Note: I reject vague "SCFM vs HP" debates. Right-size compressors using verified CFM at your working pressure (e.g., 90 psi), not marketing specs.

Related Articles

Vertical Farming Compressors: Precision Humidity Control

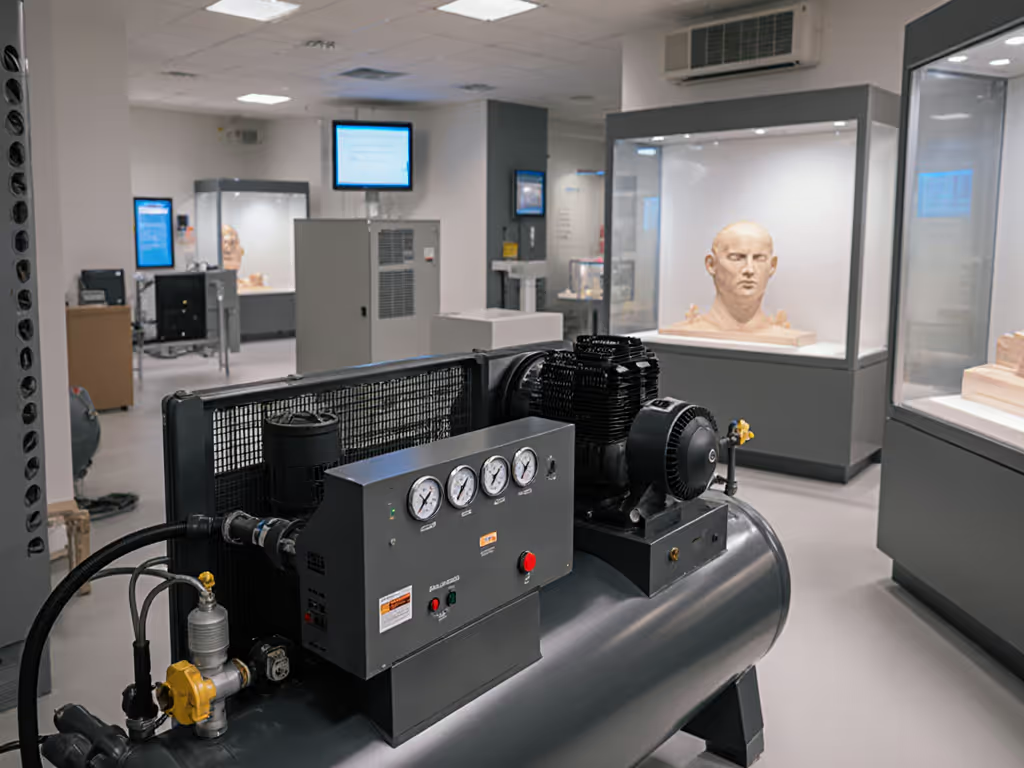

Museum Preservation Compressors: Truth Beyond Specs

Quiet Film Set Compressors: Oil-Free Air Systems Compared