Sustain Tool Performance: Air Compressor Installation Guide

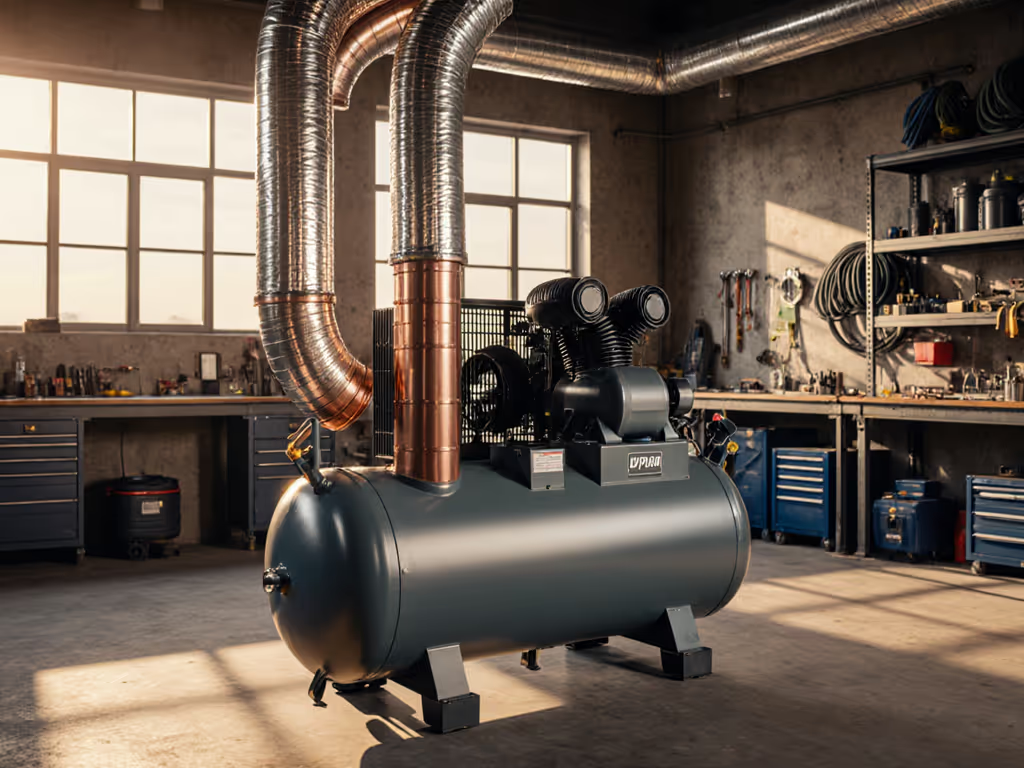

As a specialist in precision air systems for spray finishing, I've seen more tool performance failures stem from bad air compressor installation fundamentals than faulty equipment. Your compressor's rated CFM means nothing if pressure drops between tank and tool starve your HVLP gun or die grinder. Proper compressor setup best practices ensure clean, dry, stable air reaches your tool at spec pressure (not 28 PSI when you need 40). This isn't about compressor specs alone; it's about system integrity from power source to air nozzle.

Step 1: Quantify Your True Air Demand (Not Just Nameplate Specs)

Most shops fail here by using manufacturer's "peak" CFM ratings instead of actual demand at working pressure. For spray finishing, measure required CFM at your tool's minimum operating pressure, not the compressor's max PSI. For help interpreting CFM, PSI, duty cycle, and tank size, see our CFM vs PSI guide.

Critical Measurements

- Document CFM at 40, 60, and 90 PSI for each tool (not just "90 PSI" claims)

- Calculate total demand with 25% headroom for continuous operation

- Verify ambient RH. Above 50% requires drying to a dew point 20°F below ambient

I once audited a shop's "15 CFM" compressor powering a 12 CFM HVLP system. At the gun, pressure sagged to 32 PSI during trigger pull due to unaccounted pressure drop. Their rejects weren't paint issues, they were air starvation. Trace the pressure drop from tank to tool with a gauge at both points before finalizing your layout.

Step 2: Foundation Requirements and Location Analysis

Your compressor's foundation directly impacts vibration transmission and long-term component wear. Ignoring foundation requirements risks premature bearing failure and uneven stress on piping connections.

Installation Criteria

- Concrete pad minimum 6" thick, sized 6" beyond unit footprint

- Vibration isolators rated for 100% compressor weight (include tank water-weight for worst-case failure)

- Minimum 36" clearance on all sides for heat dissipation and service access

For mobile setups in vans, weld steel channels to frame members with floating mounts. Measure surface vibration; above 4 in/s RMS requires additional damping. Ambient temperature must stay between 40-110°F, which is critical for oil viscosity and condensation control. Place away from heat sources that raise intake air temperature more than 15°F above ambient.

Clean, dry, stable air makes finishes look inevitable. This starts with a stable foundation that prevents vibration-induced fitting loosening and air contamination.

Step 3: Electrical Requirements Verification

Voltage drop kills compressors. Many shops trip breakers because they ignore inrush current exceeding running amps by 6-8x. Verify these electrical requirements before installation:

- Dedicated circuit with 125% ampacity margin (e.g., 20A circuit for 16A compressor)

- Wire gauge sufficient for run length (10 AWG for 20A over 50 feet)

- Generator compatibility: verify inverter can handle 300% surge for 500 ms

Use a clamp meter to check actual voltage at compressor terminals during startup. Anything below 10% of rated voltage risks motor burnout. For 240V systems, balance loads across phases, since more than 5% imbalance causes overheating. Document voltage dip during startup; if >15%, upgrade wiring or add soft-start.

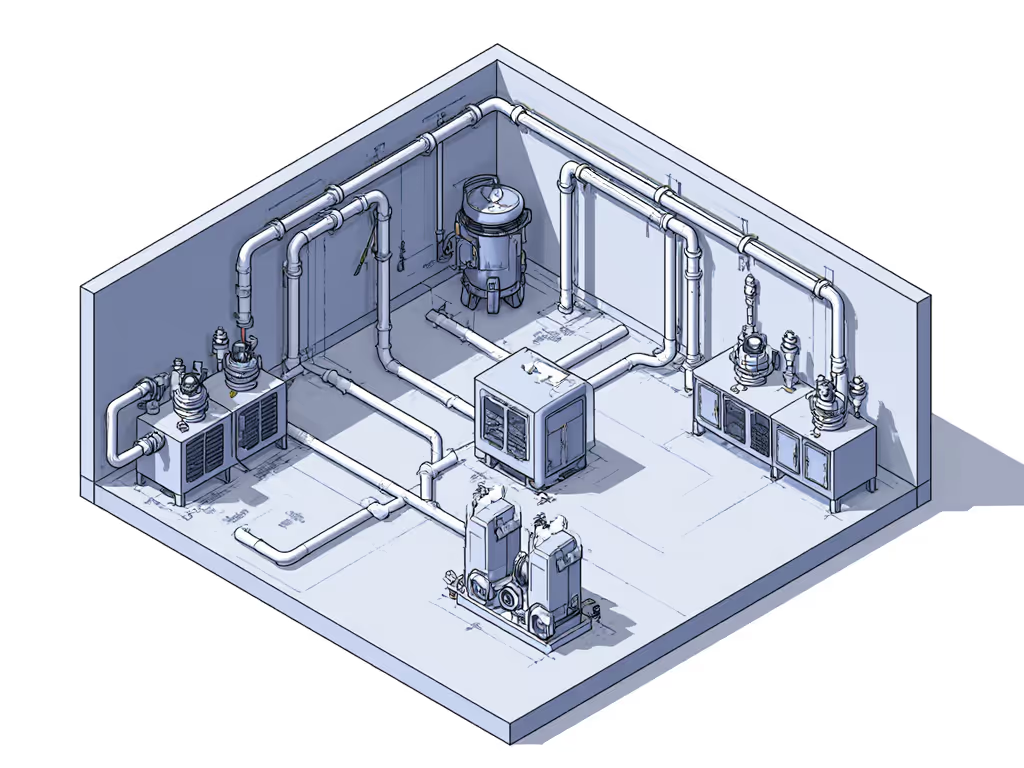

Step 4: Piping Layout Design for Minimal Pressure Loss

This is where most DIY installations fail. Your piping layout design must account for dynamic pressure loss during tool operation, not just static tank pressure.

Optimized Workflow

- Use schedule 40 black pipe for mains (min 3/4" for <20HP units)

- Slope mainline 1/2" per 10 ft toward moisture traps

- Install 3/4" drop legs with auto-drains at each branch

- Size branch lines per ISO 8573-1: 1/2" for lines <25 ft to single tool

For spray finishing stations, maintain 5/16" ID hose from regulator to gun. A 3/8" hose loses 7 PSI at 15 CFM over 25 feet, which is enough to cause orange peel. Always place the final pressure regulator within 3 feet of the tool. I've documented setups where pressure fell 18 PSI from tank to gun due to undersized elbows and coiled hoses. Trace the pressure drop at each connection point with a calibrated gauge.

Step 5: Air Treatment System Integration

Clean air requires staged filtration with micron ratings matched to your process. For paint finishing, your filtration sequence must achieve ISO 8573-1 Class 2 (1 µm) or better.

Critical Stages for Finishing Applications

- Pre-filter: 5 µm coalescing (mandatory before refrigerated dryers)

- Dryer: Refrigerated to 38°F pressure dew point or desiccant for < -40°F

- Particulate filter: 1 µm absolute (99.999% efficiency)

- Carbon filter: 0.01 µm for oil vapor (critical for water-based paints)

Verify dew point at the tool connection with a handheld meter. Ambient RH above 60% requires dryer capacity at 100% load. In that body shop with fish-eyes, we found 100 PSI at the tank but only 28 PSI at the gun with 80% RH intake air. The wet lines overwhelmed their single-stage filter. Adding a desiccant tower, regulator-at-gun, and 5/16" hose solved it. Rejects fell 90% in one week.

Document pressure drop across each filter stage; more than 3 PSI indicates overload. Change elements when drop reaches 50% of rated value, not on a calendar schedule. Ambient temperature swings require adjusting dryer capacity; for every 10°F intake rise, dryer capacity drops 15%.

Final Verification Protocol

Before declaring your installation complete, perform this validation sequence:

- Measure pressure at tank outlet during max demand

- Measure pressure at tool connection under identical load

- Calculate pressure drop (should be <10% of working pressure)

- Test dew point at tool with calibrated meter (must be 20°F below coldest surface temp)

- Verify oil content <0.01 mg/m³ for paint applications

I've seen shops skip this final validation only to battle finish defects for months. That body shop thought they had a paint problem, but they actually had an air system problem. When pressure at the tool met specifications consistently, their finishes transformed from orange peel to glass.

Proper compressor installation isn't just about the unit itself, it is about system integrity. The right foundation, electrical delivery, pipe sizing, and air treatment work together to deliver what matters: consistent, spec-grade airflow at the business end. Stop guessing about your air quality. Start measuring it at the tool where it counts.

For deeper analysis of pressure drop calculations across different hose configurations, consult ANSI/ISO 1217 Annex C test procedures. Understanding these standardized measurements separates professional setups from guesswork.

Related Articles

Robotics Air Compressor Integration: Precision CFM at 90 PSI

3D Concrete Printing Compressors: Sizing for 8 Bar Performance

AI Compressor Maintenance: Predict Failures Before They Happen