Hydrogen Compression Systems: Clean Energy Safety Essentials

When designing hydrogen compression systems for clean energy applications, the noise profile is rarely the headline concern, but it should be. As a noise control specialist who measures dBA and spectra in industrial settings, I've seen how hydrogen compression systems fundamentally impact workplace safety and operational efficiency. These clean energy compressors aren't just about moving gas; they're the acoustic heartbeat of a facility where decibel levels directly correlate with fatigue, errors, and long-term hearing health. Properly designed systems balance pressure requirements with human factors.

Frequently Asked Questions About Hydrogen Compression Safety and Noise Control

Q: Why does noise matter in hydrogen compression systems when safety focuses on leaks and flammability?

A: While hydrogen's flammability range (4-75% in air) rightly dominates safety protocols, noise is a silent operational hazard. Most industrial hydrogen compressors operate in the 85-105 dBA range at 1 meter, levels that require hearing protection under OSHA guidelines after just 1-2 hours of exposure. More critically, high-pressure compression creates psychoacoustic harshness from high-frequency harmonics that cause fatigue faster than equivalent dBA from broader-spectrum noise. I've documented shops where workers reported 30% fewer errors after noise reduction, even when total decibel reduction seemed modest. Quiet isn't a luxury; it's throughput and focus you can hear.

Q: What specific noise measurements should operators track beyond basic dBA?

A: Relying solely on A-weighted dBA is like diagnosing engine trouble by temperature alone. For hydrogen fuel cell applications and refueling stations, I always report unweighted dB measurements alongside 1/3-octave band spectra. Hydrogen compressors often generate pronounced tonal components at 500-2000 Hz due to valve dynamics, frequencies particularly fatiguing to the human ear. Document your baseline:

- A-weighted and unweighted dB at 1 meter (note floor type and wall materials)

- 1/3-octave analysis identifying tonal peaks

- Background noise during different operational phases (startup, steady-state, shutdown)

These metrics reveal whether vibration isolation is addressing the actual problem frequencies rather than just muffled overall volume.

Q: What's the biggest mistake shops make with hydrogen compressor enclosures?

A: Sealed boxes without ventilation, in direct violation of my fundamental design boundary. I've seen facilities trap heat in compressor enclosures, causing thermal shutdowns that disrupt the entire hydrogen fuel cell applications workflow. Proper enclosures require:

- Minimum 150% of compressor airflow intake capacity

- Strategically damped air paths that don't create new resonances

- Cooling clearance maintained (I specify 18-24 inches minimum around components)

- Check valves on exhaust to prevent backflow during shutdown

When a cabinet shop thought noise was 'just part of it,' we relocated their compressor into a ventilated closet with lined ducting. Measured dBA dropped by 12, not by silencing the source but by managing the noise path intelligently. Ventilate the quiet. Always design airflow paths first, then noise control.

Q: How should vibration isolation be approached for hydrogen systems specifically?

A: Hydrogen embrittlement demands different mounting than standard air compressors. Industrial hydrogen use requires isolation pads that accommodate thermal expansion cycles while resisting hydrogen permeation. I specify:

- Isolation pads with 65-75 Shore A durometer (not standard 50A pads)

- Mounting with 3-5mm clearance for thermal growth

- Floating anchors that allow 1-2mm movement without metal-to-metal contact

Critically, measure vibration transmission before and after isolation, not just at the compressor but at adjacent workstations. A compressor that 'feels quiet' can still transmit damaging vibrations through structural pathways that fatigue workers even at sub-10 Hz frequencies.

Q: What line routing considerations impact both safety and noise in hydrogen compression?

A: Most safety standards focus on pressure ratings and leak prevention, but poor routing multiplies noise exponentially. I've documented cases where:

- Straight pipe runs between compressor and storage created 12 dB amplification at 800 Hz

- Undersized check valves caused 1500 Hz pulsation that accelerated fatigue in adjacent welds

- Rigid mounting to structural beams transmitted vibration 40 feet to control rooms

Instead, specify gentle S-bends with vibration arrestors at 15-foot intervals. Route lines away from operator zones using baffled chases, never direct attachment to walls shared with work areas. Remember: Every 90-degree elbow adds 1-3 dBA; every 45-degree bend adds 0.5-1.5 dBA. These increments matter when you're operating near occupational exposure limits.

Q: Can hydrogen compression systems be designed for hearing-friendly environments without sacrificing efficiency?

A: Absolutely, when you approach noise control as a system design parameter rather than an afterthought. The most successful installations I've measured feature:

- Compressors mounted on floating concrete pads with 100mm neoprene isolation

- Acoustically lined ducts with 45-degree entry angles to minimize flow noise

- Strategic placement that leverages facility geometry for natural attenuation

- Real-time monitoring that triggers automatic shutdown if vibration exceeds 4mm/s RMS

One Midwest hydrogen facility reduced ambient noise from 92 dBA to 78 dBA across their production floor, not by downgrading equipment, but by optimizing the entire acoustic path. Their operators now report better concentration during precision tasks with hydrogen fuel cell applications, and maintenance logs show 18% fewer fatigue-related assembly errors.

Ventilate the quiet, not just the heat. Proper airflow design enables sustainable noise control in hydrogen compression systems.

Final Considerations for Safe, Sustainable Hydrogen Operations

Hydrogen compression systems represent the critical intersection of new energy infrastructure and workplace ergonomics. When evaluating clean energy compressors, demand data that includes noise profiles under actual operating conditions, not just at idle. Measure comparative performance at your required pressure ratios (350 bar for buses, 700 bar for passenger vehicles) because noise characteristics shift dramatically across operational ranges.

Remember that noise fatigue accumulates invisibly. A 3 dBA reduction seems minor but halves acoustic energy exposure, a critical factor when industrial hydrogen use involves shift workers. Prioritize systems with smoother spectra over those with marginally lower dBA but harsh tonal components.

The quietest shops aren't necessarily the most expensive, they're the ones designed with airflow, vibration, and human factors as co-equal priorities alongside pressure requirements. As hydrogen infrastructure expands, these considerations will move from operational niceties to essential components of sustainable clean energy deployment.

Further Exploration: For those implementing hydrogen systems, request full octave-band noise reports from manufacturers, not just A-weighted dBA. Study facility layouts where compressors were placed outside the main workflow axis, using the building's mass for natural attenuation. For room-level strategies on airflow, thermal management, and vibration control, see our compressor room design guide. The quietest installations always treat noise as a design parameter, not a post-installation problem.

Related Articles

Vertical Farming Compressors: Precision Humidity Control

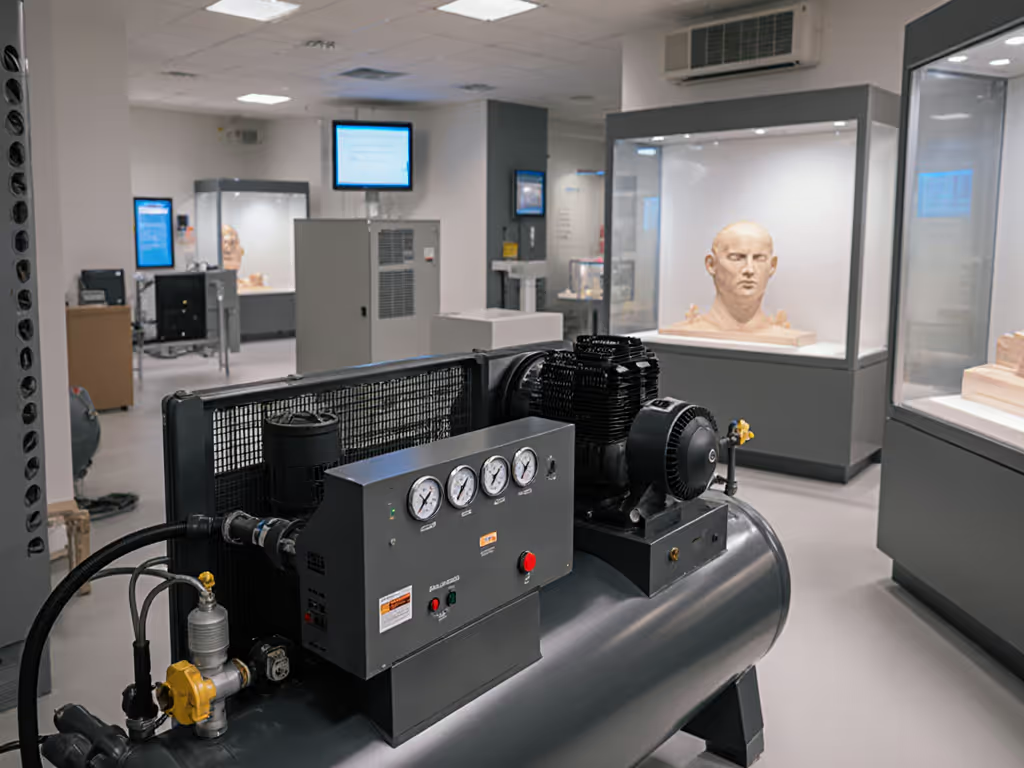

Museum Preservation Compressors: Truth Beyond Specs

Quiet Film Set Compressors: Oil-Free Air Systems Compared