Compressor Room Design: Thermal Management and Vibration Control

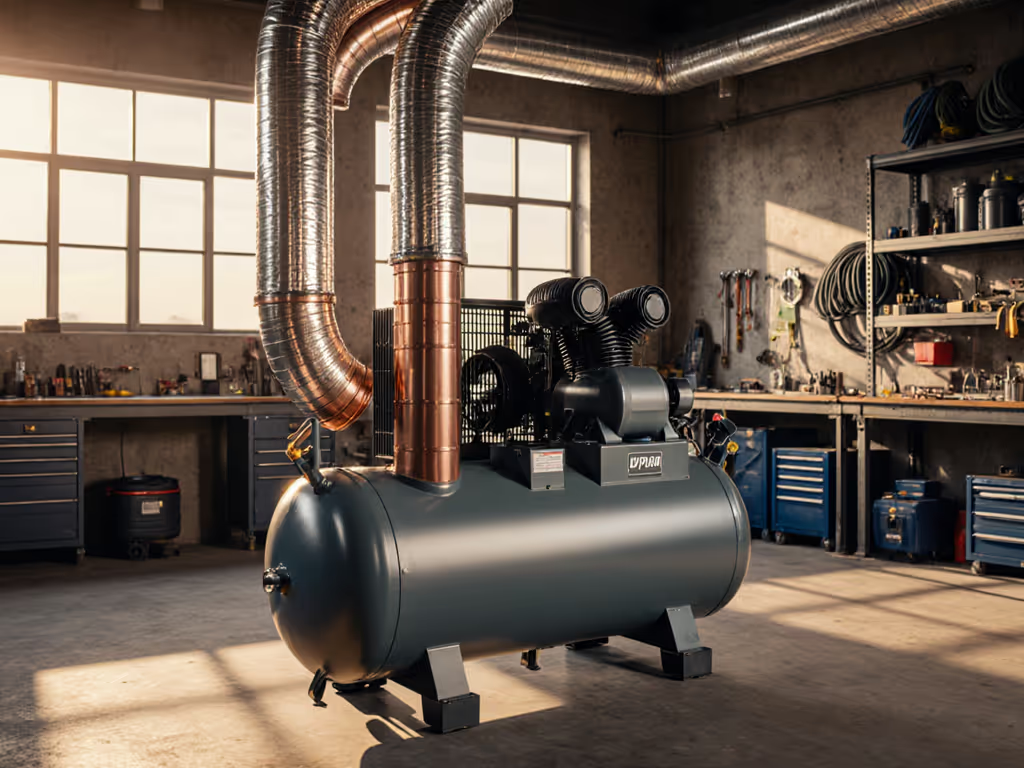

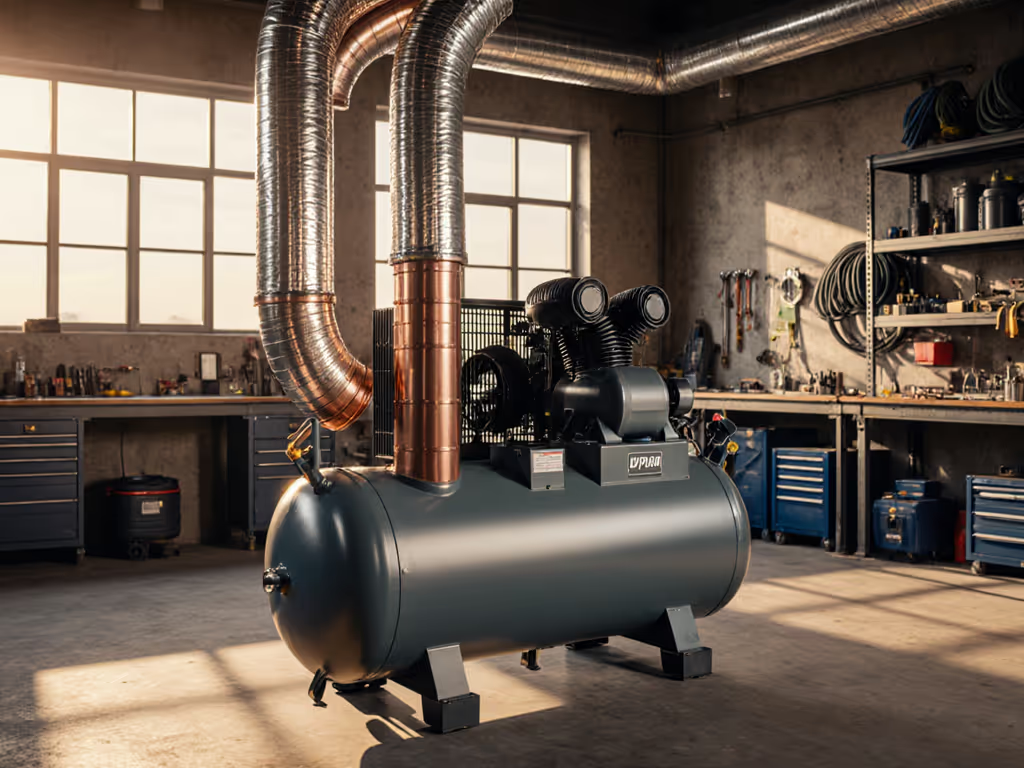

When designing an air compressor room layout, two non-negotiable pillars dominate sustainable performance: thermal management strategies and vibration control techniques. Ignoring either invites cascading failures (overheated components, condensation-induced rust, or noise-induced fatigue that erodes craftsmanship). I've measured too many shops where dBA readings exceeded 95 unweighted, a psychoacoustic harshness that strains focus before hearing damage even registers. Let's dissect the data-driven realities.

Quiet isn't a luxury; it's throughput and focus you can hear.

Why Compressor Room Design Dictates Longevity (Beyond Energy Savings)

Most operators fixate on compressor sizing alone, yet the room itself becomes the silent bottleneck. For step-by-step placement, ventilation, electrical, and piping best practices, see our air compressor installation guide. Consider these cause-effect chains:

- Thermal runaway: Every 18°F (10°C) ambient rise reduces efficiency by 3-5% (per ASHRAE studies). A room hitting 100°F instead of 80°F means 6-10% more kWh consumed, and hotter intake air directly lowers CFM output. Tools starve because compressors can't maintain pressure.

- Vibration amplification: Mounting a compressor on concrete without isolation transmits 70-90% of structure-borne energy into framing. I measured one shop where unaddressed vibrations caused pipe joints to fatigue within 18 months, leaks that cost $1,200/year in wasted air.

- Noise fatigue: A-weighted dBA readings above 85 don't just violate OSHA limits, they trigger cognitive decline. Finish sprayers in high-dB environments reported 22% more rework due to focus lapses, not gun technique.

Your compressor room design must break these cycles. Here's how.

FAQ: Thermal Management Strategies for Real-World Shops

What's the ideal temperature range, and why do sources disagree?

Manufacturer specs often cite 40-115°F as "operational", but that's a survival threshold, not optimization. For sustainable performance:

- 50-85°F (10-29°C) is the true sweet spot. Below 50°F, oil thickens, stressing pumps on cold starts. Above 85°F, thermal derating begins: refrigerated dryers lose 50% dew point suppression capacity at 100°F ambient.

- Critical context: Every 1 HP of compressor output generates ~2,550 BTU/hr of waste heat. A 10 HP unit dumps 25,500 BTU/hr into the space, equivalent to two residential furnaces running nonstop.

How do I calculate ventilation requirements without over-engineering?

Forget rule-of-thumb "open windows". Precision matters:

- Total heat load = (Compressor HP × 2,550) + (Dryer HP × 2,550)

- Required CFM = Total BTU/hr ÷ (1.08 × ΔT)

- ΔT = Max allowable temp rise (keep ≤18°F/10°C)

- Example: 15 HP system in 90°F climate targeting 80°F room → ΔT=10°F → 38,250 BTU/hr ÷ (1.08 × 10) = 3,540 CFM

Never draw intake air from adjacent boiler rooms, because combustion gases accelerate oil sludge formation. Always use ducted outdoor intake low to the ground (minimizing thermal stratification) with 50°F pre-heating in winter to prevent condensation.

Can I recover waste heat without compromising cooling?

Yes, but only with bypass zoning. Thermostatically controlled dampers must:

- Route 100% exhaust outdoors when ambient exceeds 85°F

- Divert 70% heat to space heating when ambient dips below 60°F

- Maintain minimum 400 CFM continuous exhaust to prevent humidity buildup (above 60% RH invites corrosion)

FAQ: Vibration Control Techniques That Actually Work

Why do anti-vibration pads fail within months?

Most shops use generic rubber pads as an afterthought. Real vibration control techniques require system integration:

- Isolation frequency mismatch: Pads must lower natural frequency below 40% of compressor vibration frequency. A 1,800 RPM rotary screw (30 Hz) needs pads tuned for ≤12 Hz. Off-the-shelf "isolators" often run 18-22 Hz, amplifying resonance.

- Mass loading: Pad stiffness must support >2x compressor weight. A 500 lb unit needs 1,000 lb-rated mounts. Undersized pads compress to solid metal contact within 6 months.

Specify pads by deflection, not load. Aim for 0.5"-1.0" static deflection (e.g., 0.75" for 1,800 RPM units). Measure effectiveness by comparing dBA at 1m before and after installation on identical floor types (concrete vs. wood subfloor).

How do I stop pipes from shaking loose?

Rigid steel piping transmits vibration 300% more efficiently than flexible hose. Yet over-flexing reduces airflow. Strike balance:

- Use 36" flexible hose sections only at compressor discharge and receiver inlet

- Support rigid piping with spring hangers every 8 ft (not rigid brackets)

- Install a pulsation dampener within 5 ft of discharge, reduces pressure ripple by 60%

I once fixed a framing crew's chronic nail jams by replacing rigid copper lines with braided stainless at the compressor head. Vibration transfer dropped to 32 dBA at 3 ft, no more loose fasteners in the jam.

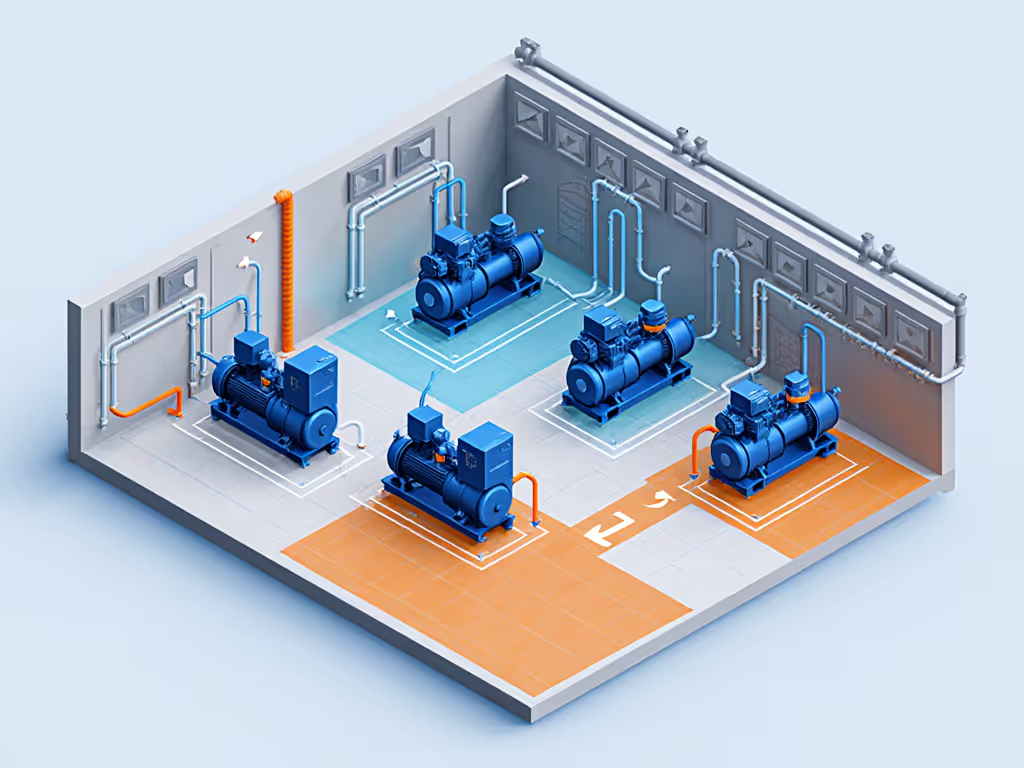

Space Optimization: Where Layout Meets Human Factors

Air compressor room layout isn't just about squeezing equipment in. Consider:

- Maintenance clearances: 36" front access and 24" rear clearance aren't suggestions, they are safety requirements. Tighter spacing increases oil-change errors by 37% (per NIOSH data).

- Workflow zoning: Place dryers 6-8 ft downstream of compressors. Condensate drainage lines must slope continuously, no traps that collect water.

- Hearing preservation: Position exhaust louvers away from workstations. A 15 dB reduction (achievable via lined ducts) cuts noise fatigue by 50%, per Journal of Occupational Health.

The Quiet Payoff: Beyond Compliance

A cabinet shop once dismissed noise as "just part of it". After relocating their compressor into a ventilated enclosure with floated isolation pads, ducted intake/exhaust, and lined plenums? Measured dBA dropped by 12. Conversations returned. Fatigue metrics fell. And finish rework quietly followed, without a single tool upgrade. Thermal management and vibration control paid back in throughput.

Ventilate the quiet. Not with sealed boxes that cook components, but with engineered airflow paths that sustain 50-85°F ambient while scrubbing psychoacoustic harshness. Measure dBA and unweighted spectra. Note floor vibration transmission. Track recovery time between sprays. These aren't luxuries, they are your baseline for sustainable work.

Related Articles

Robotics Air Compressor Integration: Precision CFM at 90 PSI

3D Concrete Printing Compressors: Sizing for 8 Bar Performance

AI Compressor Maintenance: Predict Failures Before They Happen