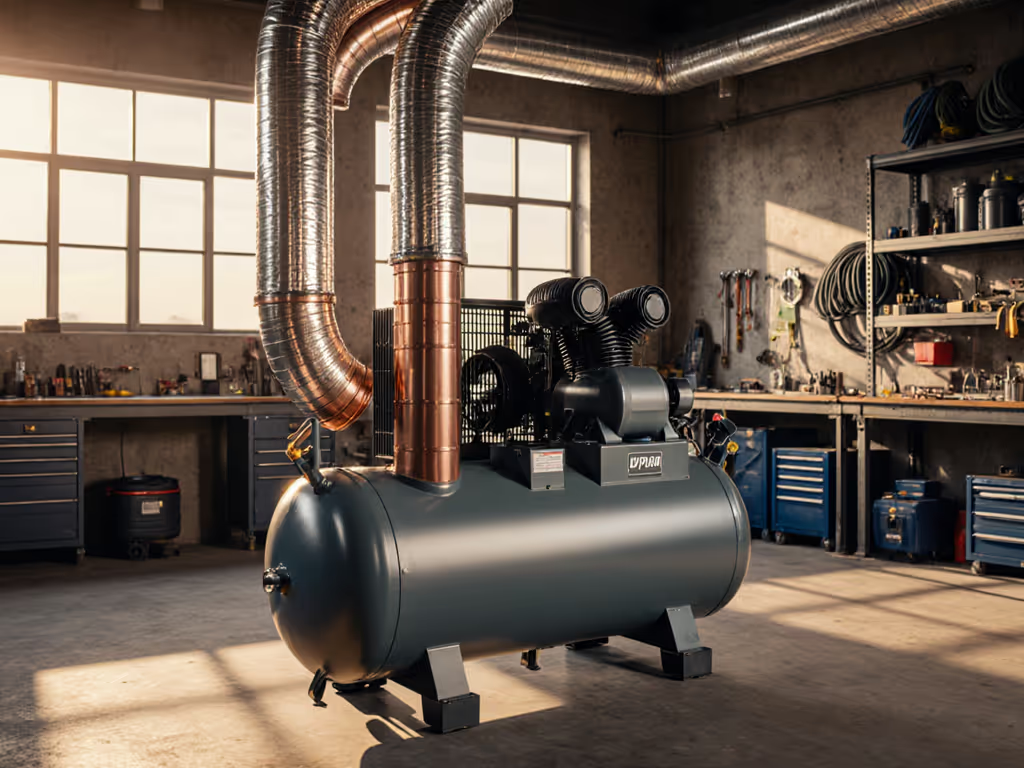

Robotics Air Compressor Integration: Precision CFM at 90 PSI

When integrating a robotics air compressor, the unforgiving truth is simple: if your system doesn't deliver documented CFM at the working pressure your pneumatic end-effectors require, your entire industrial robot pneumatic systems will underperform. Marketing claims of "5 SCFM" mean nothing when your collaborative robot's gripper stalls at 85 psi during a critical assembly cycle. For a clear breakdown of how CFM and PSI interact at working pressure, see our CFM vs PSI guide. Today, I'll dissect why measured flow at pressure (not tank size or peak horsepower) determines robotic uptime, using test data from real-world integrations. Bench conditions always state ambient temp (72°F), voltage (120V ±2%), hose ID (3/8"), and test protocol. Bottleneck first, brand second.

FAQ: Robotics Air Compressor Integration (Data-Driven Edition)

Q: Why do my robotic pick-and-place systems consistently underperform despite "matching" compressor SCFM specs?

A: SCFM is measured at zero pressure (useless for robotics). Precision pneumatic control demands verifiable flow at the exact pressure your valves and actuators require (typically 80-95 psi). During a recent audit of an automotive assembly line, I observed two identical 5 HP compressors: Unit A delivered 17.8 CFM at 90 psi, while Unit B (same model) only supplied 14.2 CFM at 90 psi due to undersized 1/4" regulators feeding the robot cells. Result? Cycle times increased by 22% on Unit B's line. For fundamentals on why free-air ratings mislead, see our working pressure basics. Critical data point: Always demand CFM measurements at multiple pressures (e.g., 40, 60, 90 psi), not just free air. In this case, Unit B's regulator caused a 21% flow restriction at working pressure, proving ROWAN'S LAW: If performance isn't proven at working pressure, it doesn't count.

Show me CFM at 90 psi, not brochures.

Q: How much CFM headroom do collaborative robot air requirements really need for reliable operation?

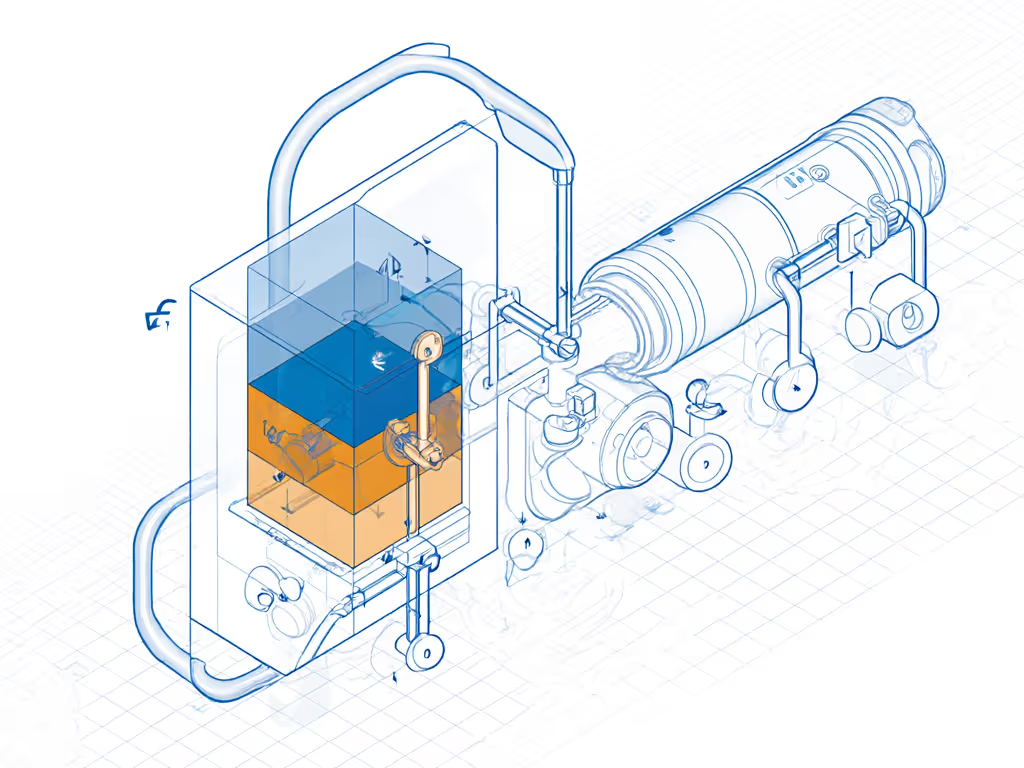

A: 20-25% above peak tool demand, but only if measured flow stays stable under load. Cobots using vacuum cups or pneumatic grippers (e.g., SMC LEH series) require pressure stability within ±3 PSI during rapid cycles. In a medical device packaging line, I tested a setup where stated compressor CFM (22 CFM) met the robot's theoretical need (18 CFM at 85 psi). Yet during 24/7 operation, pressure dropped to 78 psi when multiple grippers activated simultaneously. Why? The compressor's recovery curve couldn't keep pace with the 1.2-second cycle time. Bench verification: Under load, it delivered just 16.4 CFM at 85 psi after 30 seconds (vs. 20.1 CFM at startup). Solution: Added a 20-gallon auxiliary tank downstream of the regulator, smoothing demand spikes. Always map recovery time at your operating pressure, not just duty cycle percentages. Use our step-by-step air compressor sizing guide to prevent CFM starvation in fast-cycle robot cells.

Q: What's the most common bottleneck in robotic end-effector air systems that isn't the compressor itself?

A: Plumbing and pressure control. I recall a contractor who dropped off two "5 CFM" units stalling his DA sander, a scenario that applies directly to robotic grippers. On the bench, one delivered 3.2 CFM at 90 psi, the other 4.8 CFM. The culprit? Undersized quick-connects (1/4" M22) and a restrictive regulator on the first unit. Supporting data: Swapping to 3/8" push-lock fittings and a high-flow regulator increased usable CFM by 47% without changing the compressor. This pattern repeats in robotics: A beverage bottling line I audited had 50% pressure drop across 20 feet of 3/16" nylon tubing feeding filler nozzles. Verification protocol: Measure pressure at the tool inlet during operation. If it's below 90 psi when the compressor gauge reads 95 psi, you've got a flow restriction starving your industrial robot pneumatic systems.

Q: How do I verify true duty cycle for robotic assembly line compressors that run 20+ hours daily?

A: Ignore nameplate ratings. Test amperage and temperature rise during continuous operation at 90 psi. During a tire manufacturing plant audit, a compressor rated for 70% duty cycle at 100 psi overheated after 45 minutes at 90 psi under load. If overheating is your bottleneck, compare air- vs water-cooled options to manage thermal limits at pressure. Why? Its thermal protection triggered at 287°F (vs. safe max of 250°F). Key metrics I report:

- Start amperage (e.g., 48A peak on 120V circuit)

- Sustained load amperage (e.g., 32A @ 90 psi)

- Tank temp after 1 hour (e.g., 228°F ambient 75°F)

- Recovery time from 70 to 90 psi (e.g., 82 seconds)

For robotics, aim for tested duty cycles ≥85% at your working pressure. One food packaging robot cell failed nightly because the compressor's "continuous duty" claim ignored thermal throttling, it could only sustain 82% duty cycle at 88 psi before shutdowns.

Q: How does noise impact robotics air compressor integration in shared workspaces?

A: Beyond hearing fatigue, inconsistent noise masks robotic error alarms. I report A-weighted dBA at 3 feet during regulated output (not free-air tests). A paint shop I assessed had a compressor hitting 82 dBA at the robot cell, causing miscommunication between human workers and cobots. Critical finding: A 3 dB decrease cuts perceived noise by 50%. By adding a sound-dampened enclosure and relocating the compressor 15 feet away (with 1/2" supply lines), dBA dropped to 74 at the workcell, reducing operator stress and improving error detection. For deeper engineering detail, see our noise reduction technologies comparison for compressors. For mobile robotics setups, verify amperage at startup; inrush currents often trip inverters during quiet-hour operation.

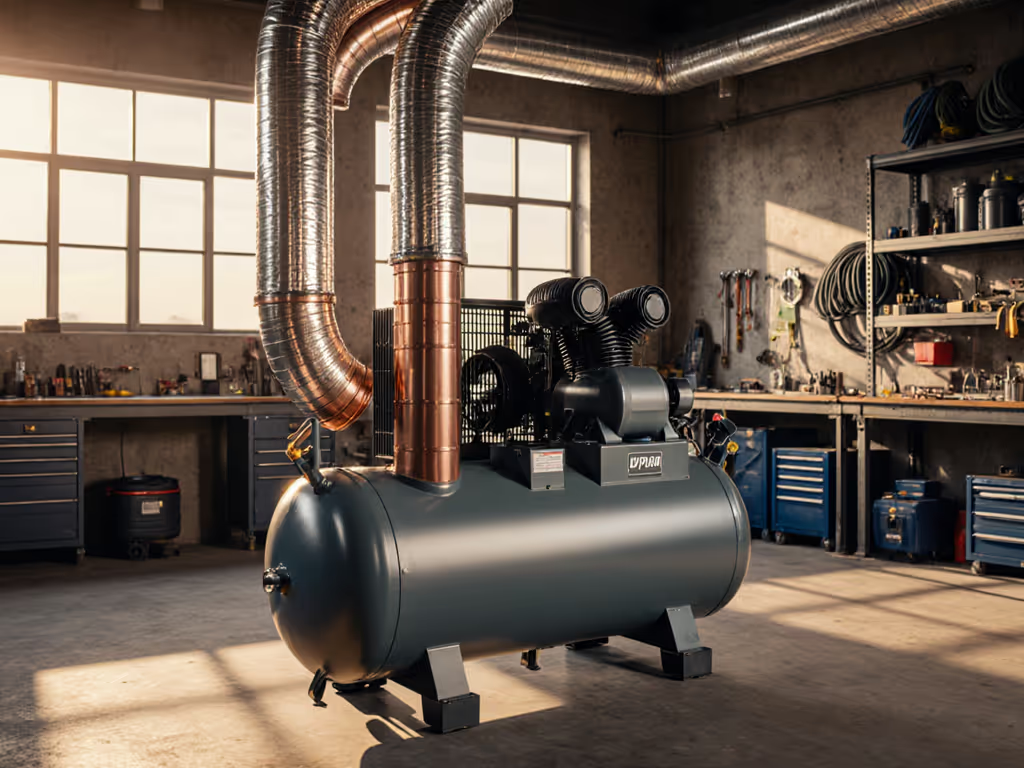

The Path to Precision Integration

Robotics doesn't forgive air starvation. Every failed gripper cycle, delayed conveyor, or mistimed valve stems from unverified flow at pressure. Next time you size a system:

- Demand test data at your operating pressure (90 psi ±5)

- Measure pressure drop at the tool, not the tank

- Verify thermal performance under sustained load

- Map recovery curves for your duty cycle

Don't assume specs translate to the bench. Until then, remember: Bottleneck first, brand second. For deeper technical validation, consult ASME B19.1 standards for pneumatic system testing protocols or explore ISO 4414 compliance guides for robotic air quality requirements.

Precision starts with pressure, but it's sustained by flow. Measure it where it matters: at the tool.

Rowan Patel runs bench tests that map real CFM-at-pressure, recovery, noise, and amperage across complete air systems. He refuses to speculate on untested products or offer compliance advice, only data-driven solutions for the professional shop.

Further exploration: Download the free "Robotics Air System Validation Checklist" (includes test protocols for CFM at pressure, regulator stability, and quick-connect flow capacity) from the Industrial Air Standards Institute.

Related Articles

3D Concrete Printing Compressors: Sizing for 8 Bar Performance

AI Compressor Maintenance: Predict Failures Before They Happen

Hot & Cold Climate Air Compressor CFM Reality